Many other GT40 replica-makers try to closely emulate the mechanicals of the original car, allowing for an authentic experience. But that of course comes at the expense of the driveability and creature comforts we’ve all become accustomed to in the modern age. CAV decided to do things differently by creating cars that are still as close to the original as possible when it comes to design, but step things up when it comes to the overall driving experience. Company CEO Jordi Reddy took over CAV in 2013, and that’s when the focus was shifted towards creating the world’s best modern GT40 replica – the CAV GT.

In 2016, CAV relocated to their current facility, where design, body and component manufacturing, paintwork and final assembly is all handled in house.

Every CAV GT begins life as a photo on a customer’s wall, a roll of fiberglass, and some steel sheets and tubes. As an order comes in, the GT’s inception begins as a mix of handcrafted skill and cutting-edge technology – not to mention many man hours.

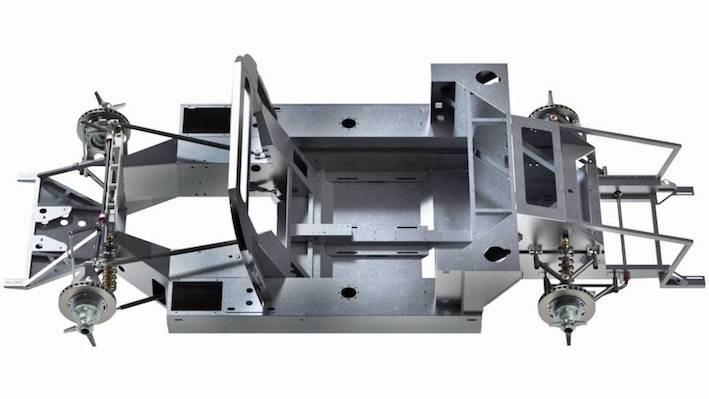

Unique to CAV is a stainless steel monocoque chassis, designed for rigidity and able to accommodate drivers up to 6’4″ in height. CAV produce the only Ford GT40 replica in the world with this type of chassis.

Chassis panels are laser-cut and bent to specific tolerances, as are the bespoke CNC-machined aluminium components. In the welding bay, the chassis and other various components are meticulously assembled and welded piece by piece in their respective jigs. Typically, the team have the manufacture of a complete chassis down to four days, including all quality checks.

The bodies themselves are an absolute work of art, although they don’t look that way when starting out. Beginning with fiberglass moulds, each CAV GT body is individually shaped and finished.

Once the body is ready, the shaping department begins the process of mating the panels to its corresponding position on the chassis. Most of the build time is spent here, ensuring a millimeter-perfect body fit. Even if you order your CAV GT40 OZ Edition without the paint option, CAV will still insist on finishing off the body fit, a job that will save you many hours with your build… and it’s all included in the price.

After sign off, body shaping and custom upgrades, such as ‘Gurney Bubbles’ or snorkels can be fitted. Finally, the body is carefully gapped before preparing for paint. (if paint option is chosen)

The Gulf Oil liveried car is an extremely popular exterior scheme for these cars and CAV offers the world’s only officially licensed Gulf Oil replica GT40. A license fee is payable to Gulf Oil so this is the most expensive paint option. You can choose any colour you like for a fixed price (some metallic and 3 layer paints will cost extra… once you choose your colour CAV will provide a fixed price). Having a spray booth in-house allows the team to keep a close eye on every stage of the painting process and address any concerns as and when they happen, allowing for the best possible finish.

In the booth, the body undergoes a rigorous priming and surface preparation process to ensure every last imperfection is eliminated.

For painted stripes and Gulf liveries, everything is meticulously measured and masked by hand. This intricate process ensures that after the final layers of paint are sprayed and the body has been polished, striping is undetectable by touch.

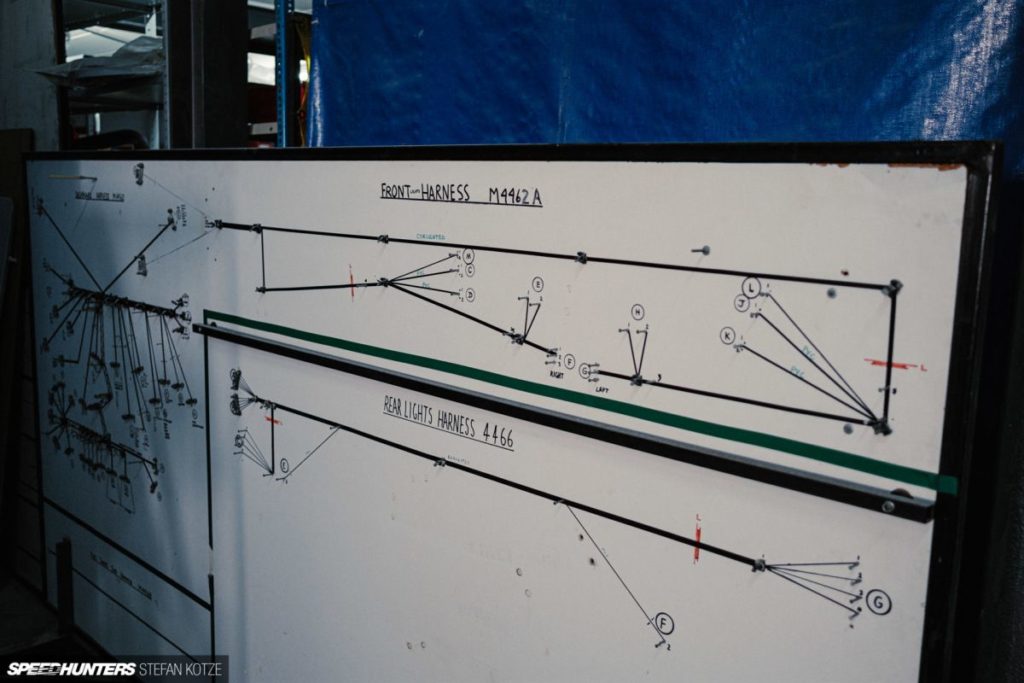

Throughout the body and paint process, various sub-assemblies, first stage production and electrical components are assembled and boxed for shipment.

CAV’s storeroom is where all the smaller parts are kept, with countless little items neatly named and organized for shipping.

Another key part of a CAV GT build is the interior, which can be customized with a few options according to a customer’s needs. All the cars carry hand-stitched and upholstered custom-designed panels and seats in European-spec leather, with historic eyelet details for the ultimate ergonomic GT40 experience.

Because CAV is a low-volume company, they can also take on certain individual requests. For instance, the brown leather above was supplied by the customer as it’s the exact material he wanted. He also had some driving gloves made up with the same material.

All the analog gauges and switchgear look really great and timeless. You’ll also notice that on some of the cars the switches are exposed, where on the car with the black interior the switches have aluminium covers over them. This is because of a UK safety requirement however as it is not a requirement in Australia, you can choose what style you prefer. Each CAV GT OZ Edition also comes with a fully adjustable pedal box.

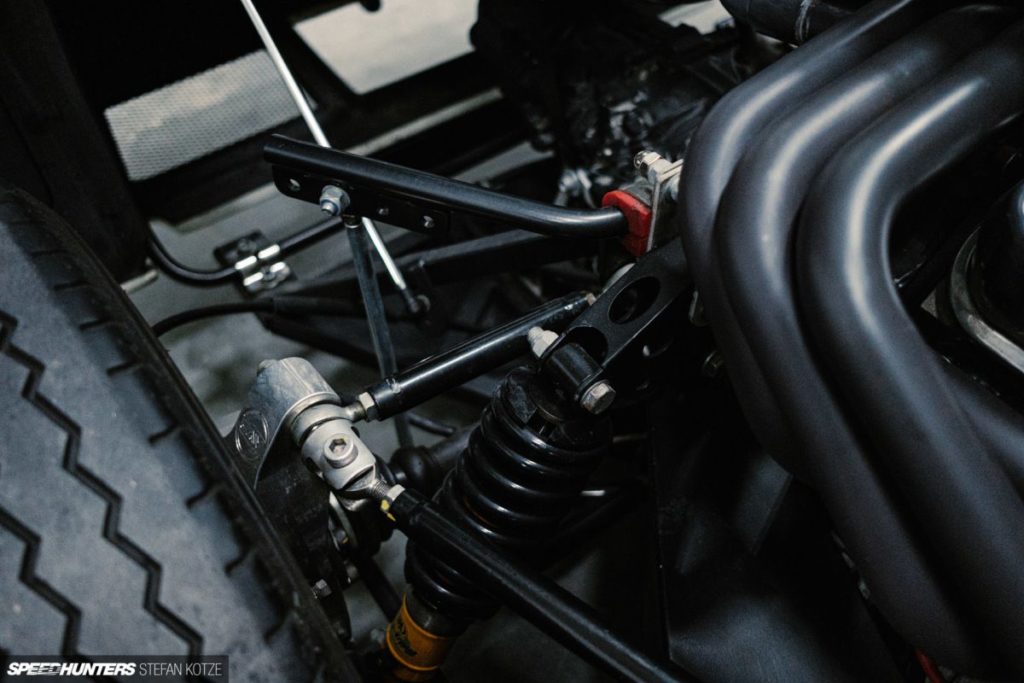

Adjustable lightweight dampers are standard on the CAV GT40 OZ Edition, allowing the customer to adjust bump and rebound with ease. The suspension uprights are bespoke to CAV and machined from billet aircraft-grade aluminium.

Customers can also upgrade to fully adjustable rose-jointed suspension, where you can fine tune castor, camber, toe-in and bump steer.

When it comes to powerplant options, under the Individually Constructed Vehicle requirements, you cannot import the engine into Australia in the same container as your kit. Therefore the best choice to comply with Australia’s strict emission regulations is the Ford Mustang Gen 2 5.0 L Coyote engine producing 435hp that accommodates Ford’s CMCV valve system. Paul’s demo vehicle will have this engine fitted and he is going with an 8 stack injection system plus a Motec engine management system with an expected output of 530hp.

The dual fuel tanks are a baffled aluminium design with a rear catch can. Each kit includes a beautifully crafted stainless steel exhaust system to let the the V8 engine sing.

Multiple wheel options are available to suit individual needs, and include 15-inch BRM, 15-inch Hallibrand, 17-inch Hallibrand and 15-inch BRM in Gulf orange. Tyre choices for the wheels are all dependent on the customer’s preferences and budget. As mentioned, the wheels cannot be imported with your kit so talk to Paul about wheel options and prices.

When it comes to stopping power, the standard options are Wilwood 4-pot fronts and rears with bias control is the standard fitted option, while customers can also upgrade to a big brake kit if desired. Talk to Paul about other brake options.

The recommended transmission is the Audi 01E 6 speed due to price and availability. Other more expensive options are the Porsche 6-speed gearbox or the tried and trusted ZF 5-speed unit. As mentioned, the transmission cannot be imported with your kit so talk to Paul about options and prices. Depending on the car’s use, either a copper button or organic woven clutch can be selected.

The process comes to an end with a final and extensive quality control check of the body, chassis and components, then it’s loaded into a 20ft container and it’s on it’s way to you!

Paul’s job is to help you with the whole process from start to finish including helping you choose options, paint colours, engine and gearbox choice, shipping & customs clearance and regulatory requirements. As he has gone through this exact process himself he know how to import your kit in the most cost effective and efficient manner possible and also offers invaluable help with the build process.